Heat Recovery – Or How To Afford Yourself a New Mercedes Every Year

Are you ready to drive off in a new Mercedes every year without breaking the bank? Dive into the world of heat recovery systems where cost-efficiency meets environmental consciousness. Discover how you can revolutionize your production process while saving money and saving the planet!

In this article:

- Uncover the secret to affording a new Mercedes annually through heat recovery systems.

- Learn how heat recovery can enhance your production’s cost efficiency and competitive edge.

- Explore examples showcasing the incredible savings and environmental benefits of heat recovery.

- Find out how your industrial operation can tap into waste heat potential for substantial energy savings.

- Meet Maxxtec, your partner in implementing cutting-edge European technology for sustainable energy solutions.

Who would not like to know how it would be possible to afford a new Mercedes every year, solely through the savings by a heat recovery system? In other words, you can also call it “reduced production costs”.

This increases the cost efficiency of your production and thus increases the competitiveness of your products. In addition, recovering waste heat can also generate significant cost savings, help saving fossil energy and therefore protect the environment for our children.

Almost every week, you can expect news about rising energy costs. Many efforts are being made in industrial operations to reduce energy consumption of the production. Most companies invest in better and more efficient production machines, high- efficient electric motors and LED lighting, even though the results of this type of saving are often not impressive and the costs are high. Not many are aware of how much energy can actually be saved by replacing fossil fuels with the recovery of existing heat.

Many industrial processes, ovens, engines or high temperature process heaters (thermal oil heaters or steam boilers) release waste heat on a high temperature level to the atmosphere. This is very unfortunate, since the energy can not only be used to generate process heat, but also to generate electrical energy, or even chilled water.

The value of the saved fossil fuel is often easily equal to the value of a pretty nice Mercedes Benz car. Therefore, the result shows impressive payback and ROI numbers.

We have installed quite a lot of heat recovery systems during the last decade, in various industrial operations. In most of the cases, the investment for this kind of system is manageable and the amortization is done in a few years.

This calculation neither includes the future increasing costs for fossil fuels, nor does it include the significantly reduced maintenance costs, compared to burners or furnaces for fossil fuels.

In the following we want to give you a few examples for different heat recovery concepts.

Example 1, Thermal Oil Heater for process heat supply

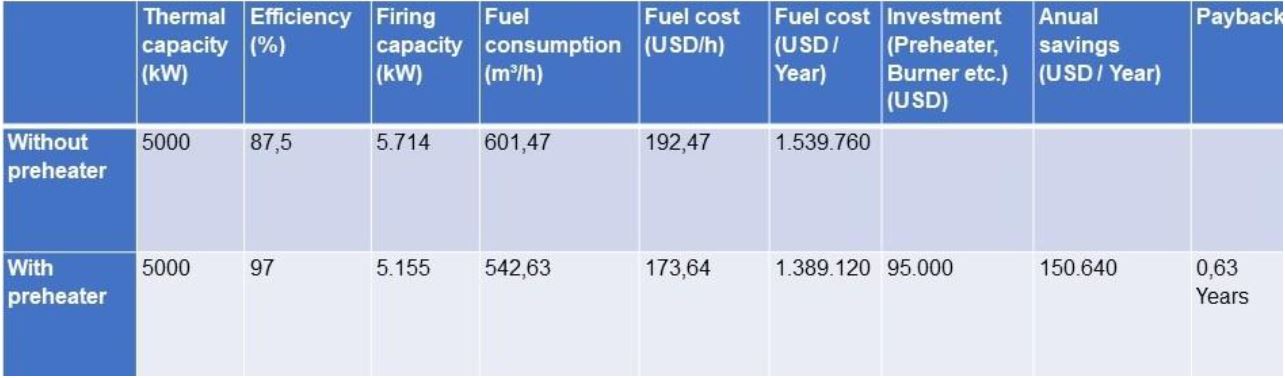

Fuel Natural Gas (US$ 10,-/mmbtu = US$ 0,32/m³), heating value 9,5kWh/m³, operation 8000h / Year, Heat use: Pre-heating of the combustion air

Fuel: Coal, heating value 3500kcal/h (4,1kW), Efficiency, coal fired heater 76%, heat use: Process heat for flash dryer, Heat Recovery from 3 Biogas Engines 1.800kW, operation 8000h/Year

Example 3, Heat Recovery from a drying channel for plastic foil

Fuel Natural Gas (US$ 10,-/mmbtu = US$ 0,32/m³), heating value 9,5kWh/m³, operation 8000h / Year, Heat use: Pre-heating of the drying air

Impressed? In most of the industrial productions there is a useful waste heat potential. If not, there are still other production residues, which could also potentially lead to energy savings.

In any case, we are the right partner to help you achieve your goals. If you have any questions, feel free to contact us.

Besides the realization of corresponding systems, we are also gladly available for the identification of corresponding potentials, as well as for the necessary analysis, measurements and conceptions.

PT Maxxtec Teknologi Indonesia has been established 2014 to bring innovative European Technologies to South East Asia. Our aim is to improve energy efficiency of local productions in order to increase cost efficiency and to help protect the environment.

We are a team of very experienced german Specialists and highly educated local engineers, who design solutions based on the latest german Technology, with highest german Quality Standards, while producing here in South East Asia.

Our Office is located in South – Jakarta, where we do research, development, engineering, design, project management, production supervision, site services, as well as spare part-, maintenance- and repair services for all of our products and solutions.

We would be pleased to assist you with any questions.

CONTACT

PT Maxxtec Teknologi Indonesia

ITC Permata Hiljau, Lantai 3 C11 No. 16, Jl. Arteri Permata Hijau, Kebayoran Lama, 12210 Jakarta Selatan, Indonesia

Telephone: +62-21-53670749

Email: teknologi@maxxtec.co.id